أهم الميزات التي يجب البحث عنها في شاشة لوحة التحكم في التشكيل الحراري

Choosing the right thermoforming control panel is crucial for ensuring efficient, safe, and precise operation in modern manufacturing environments. From user-friendly interfaces to real-time monitoring, a high-quality thermoforming control panel display can significantly enhance productivity and minimize downtime. This guide covers the most important features to consider, explains how they can impact production, and explores […]

التشكيل بالضغط مقابل التشكيل الحراري: الاختلافات الرئيسية

Compression Moulding vs Thermoforming: Key Differences Compression moulding involves placing a moulding material in an open, heated mould cavity. Pressure forces the material to contact all mould areas. Thermoset composites often serve as the primary material in this process. Prepreg materials, pre-mixed materials, and blanks are common choices. In contrast, thermoforming uses heated plastic sheets shaped by vacuum […]

كيفية عمل أنظمة التبريد بالتشكيل الحراري

How Thermoforming Cooling Systems Operate Thermoforming involves shaping a heated thermoplastic sheet over a mould. The process relies heavily on energy, with the heating system consuming more than 70% of the energy requirement. Basic principles of thermoforming include heating, moulding, and cooling. Cooling plays a vital role in solidifying the formed sheet, ensuring product quality and integrity. […]

تحسين جودة الأجزاء المشكّلة بالحرارة باستخدام تقنية مضخة التفريغ: دليل شامل

Optimizing Thermoformed Part Quality with Vacuum Pump Technology: A Comprehensive Guide Thermoforming remains a crucial process in manufacturing, shaping plastic sheets into precise forms. This method is highly significant due to its efficiency and versatility. The global market for thermoformed plastics is anticipated to expand considerably, reaching approximately USD 74.12 billion by 2034. Vacuum pumps […]

لماذا تُعد الصواني المشكّلة بالحرارة مثالية لاحتياجاتك من التغليف

Why Thermoformed Trays Are Ideal for Your Packaging Needs Thermoformed trays offer a versatile packaging solution for various industries. These trays provide cost-effectiveness, durability, and customization capabilities. The right packaging solution ensures product safety and enhances brand reputation. Thermoformed trays cater to specific needs with precision and efficiency. Businesses benefit from reduced costs and improved […]

تحليل نمو سوق التغليف البلاستيكي المشكل بالحرارة

Thermoformed Plastic Packaging Market Growth Analysis Introduction Thermoforming involves heating a plastic sheet until it becomes pliable and then molding it into the desired shape. The process creates durable, lightweight, and cost-effective packaging solutions. Market growth analysis plays a crucial role in understanding the dynamics of the packaging industry. Analyzing market trends, growth factors, and […]

عملية الضغط المزدوج المتقدمة: تحسين جودة وكفاءة صب حاويات البولي إيثيلين تيرفثالات البولي إيثيلين تيرفثالات المشكل بالحرارة

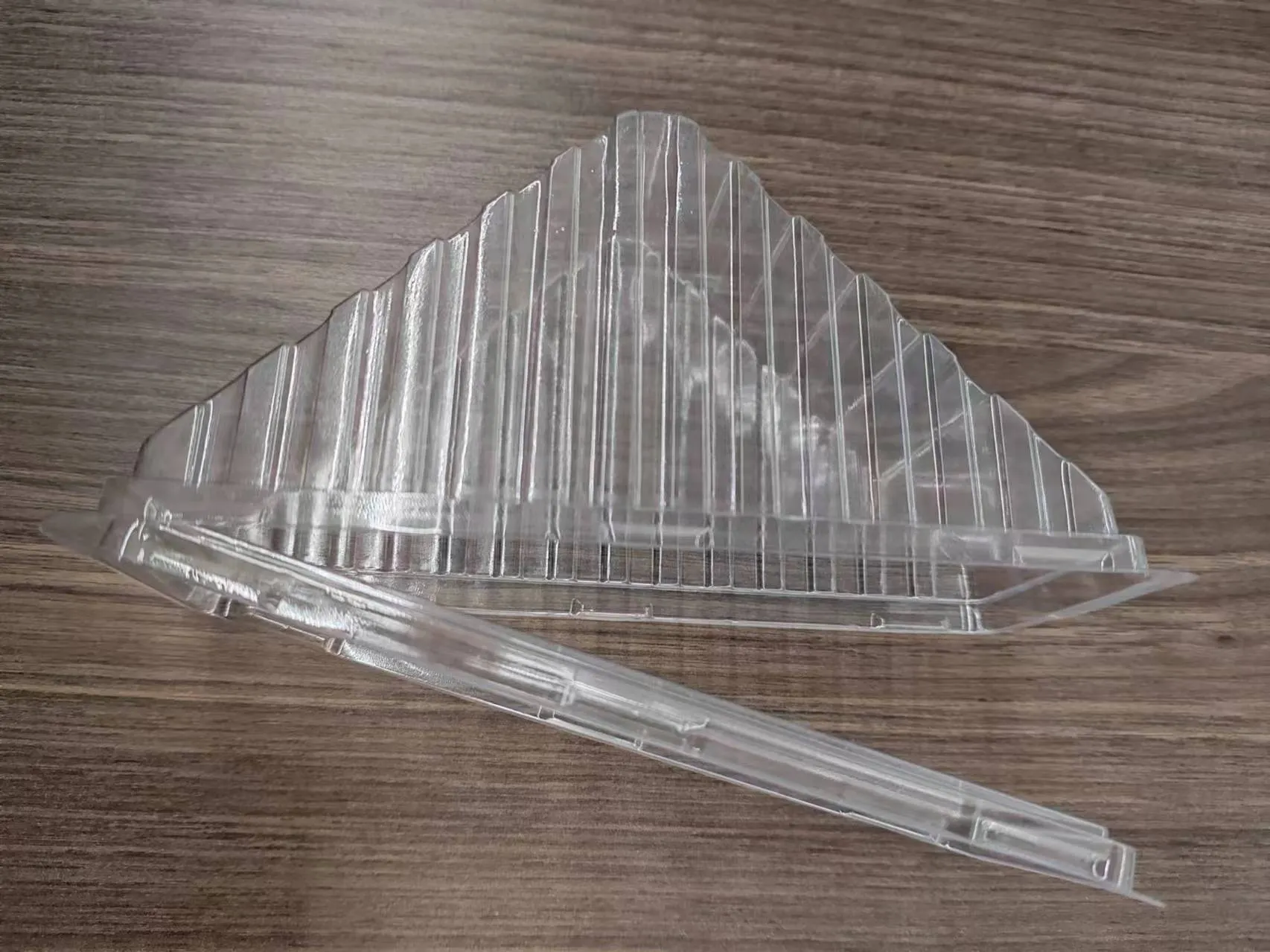

Advanced dual-pressure process: improving the quality and molding efficiency of clamshell thermoformed PET containers The secret: advanced thermoforming technology The process of creating clamshell thermoformed PET containers is the cutting edge that sets industry leaders apart – thermoforming. Unlike traditional methods that rely solely on vacuum forming, we use a state-of-the-art dual pressure method – […]

تطبيقات وفوائد حاويات البولي إيثيلين تيريفثاليت البولي إيثيلين تيريفثاليت الصغيرة المشكّلة بالحرارة

Applications and Benefits of Small Clamshell Thermoformed PET Containers Overview: Introduction to Small Clamshell Thermoformed PET Containers In the packaging sector, innovation is the key to stand out in a competitive market. Small clamshell thermoformed PET (polyethylene terephthalate) containers are one such innovation. These containers have revolutionized the packaging industry with their versatility, sustainability, and […]

محطة التثقيب والقص لماكينة التشكيل الحراري متعددة المحطات: جوهر التصنيع الدقيق

Introduction Multi-station thermoforming machine plays a vital role in modern manufacturing, especially in the field of plastic products. Its integrated multiple process steps can efficiently process plastic materials into various required shapes and structures. Punching and shearing station, as one of the key steps, plays an irreplaceable role. This article will discuss the punching and […]

شرح تفصيلي لتقنية التشكيل الحراري للبلاستيك الشفاف: اختيار المواد وتدفق العملية ومجال التطبيق

Detailed explanation of transparent plastic thermoforming technology: material selection, process flow and application field Introduction Transparent plastics are popular for their high transparency, good mechanical properties and wide application fields. Among the many molding methods, thermoforming is an important and better technology, especially suitable for the production of transparent plastic products with large size and […]