الاختيار بين القوالب الإيجابية والسلبية في التشكيل الحراري: الاعتبارات الرئيسية للتصنيع الدقيق.

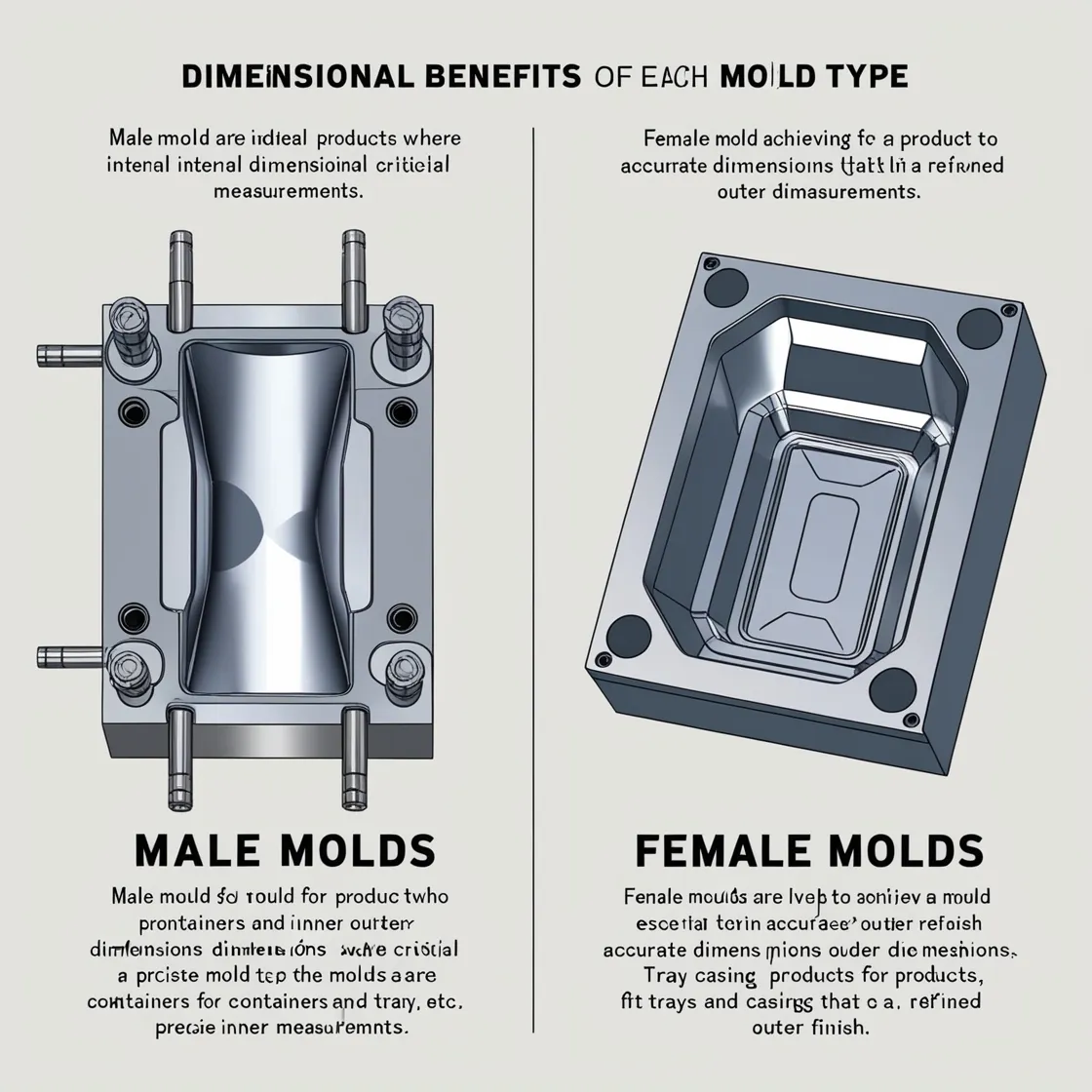

In thermoforming, mold selection is central to achieving desired product quality, precision, and manufacturing efficiency. The two primary types of molds—male (positive) and female (negative) molds—each impart unique benefits and limitations, making them suited to specific applications within thermoforming. This guide provides an in-depth comparison of these molds to help manufacturers optimize their process and […]

كيفية عمل أنظمة التبريد بالتشكيل الحراري

How Thermoforming Cooling Systems Operate Thermoforming involves shaping a heated thermoplastic sheet over a mould. The process relies heavily on energy, with the heating system consuming more than 70% of the energy requirement. Basic principles of thermoforming include heating, moulding, and cooling. Cooling plays a vital role in solidifying the formed sheet, ensuring product quality and integrity. […]

تحسين جودة الأجزاء المشكّلة بالحرارة باستخدام تقنية مضخة التفريغ: دليل شامل

Optimizing Thermoformed Part Quality with Vacuum Pump Technology: A Comprehensive Guide Thermoforming remains a crucial process in manufacturing, shaping plastic sheets into precise forms. This method is highly significant due to its efficiency and versatility. The global market for thermoformed plastics is anticipated to expand considerably, reaching approximately USD 74.12 billion by 2034. Vacuum pumps […]

تطبيقات وفوائد حاويات البولي إيثيلين تيريفثاليت البولي إيثيلين تيريفثاليت الصغيرة المشكّلة بالحرارة

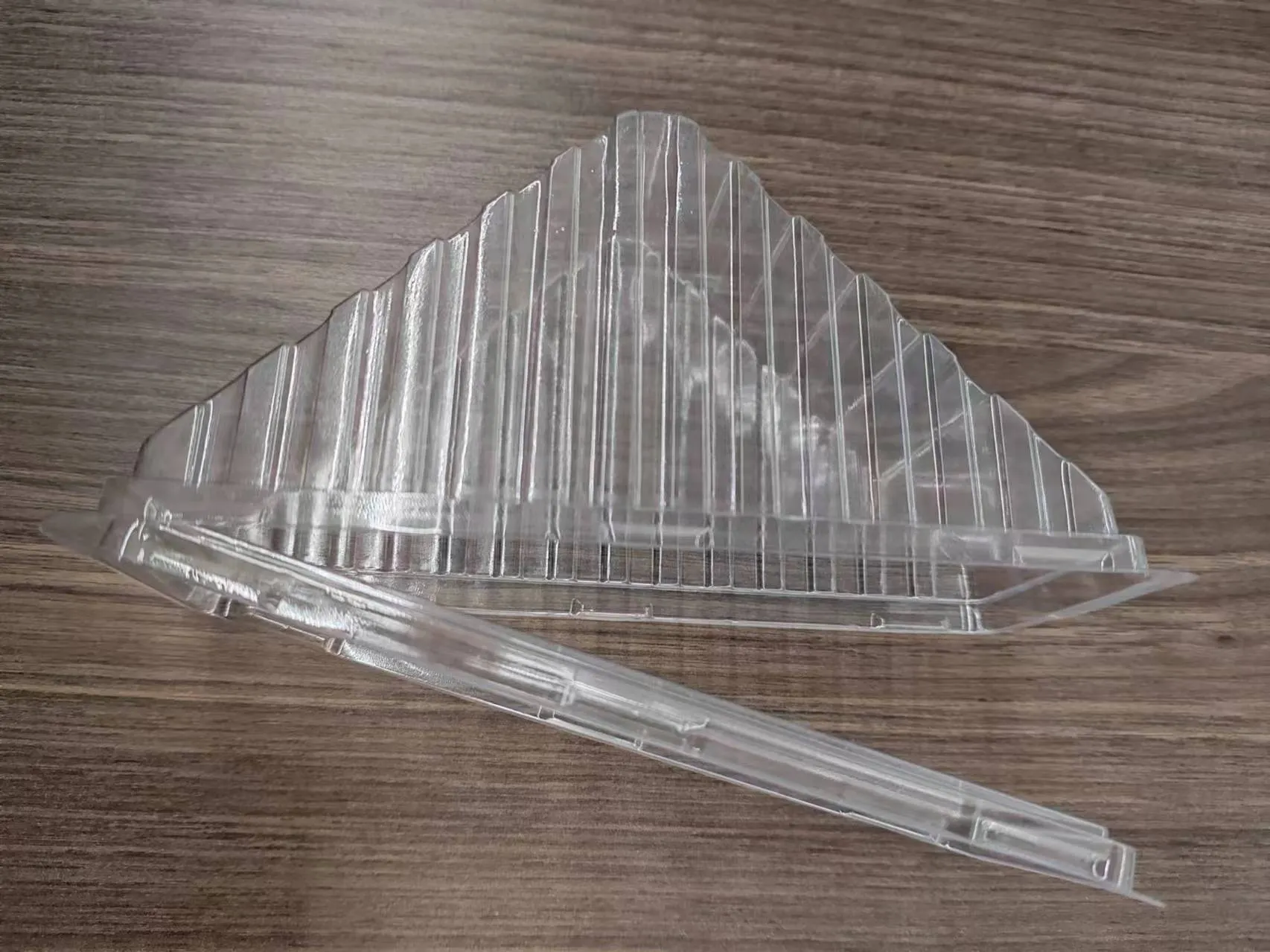

Applications and Benefits of Small Clamshell Thermoformed PET Containers Overview: Introduction to Small Clamshell Thermoformed PET Containers In the packaging sector, innovation is the key to stand out in a competitive market. Small clamshell thermoformed PET (polyethylene terephthalate) containers are one such innovation. These containers have revolutionized the packaging industry with their versatility, sustainability, and […]

محطة التثقيب والقص لماكينة التشكيل الحراري متعددة المحطات: جوهر التصنيع الدقيق

Introduction Multi-station thermoforming machine plays a vital role in modern manufacturing, especially in the field of plastic products. Its integrated multiple process steps can efficiently process plastic materials into various required shapes and structures. Punching and shearing station, as one of the key steps, plays an irreplaceable role. This article will discuss the punching and […]

شرح تفصيلي لتقنية التشكيل الحراري للبلاستيك الشفاف: اختيار المواد وتدفق العملية ومجال التطبيق

Detailed explanation of transparent plastic thermoforming technology: material selection, process flow and application field Introduction Transparent plastics are popular for their high transparency, good mechanical properties and wide application fields. Among the many molding methods, thermoforming is an important and better technology, especially suitable for the production of transparent plastic products with large size and […]

حل مشكلات التسخين في آلات التشكيل الحراري متعددة المحطات: الخطوات الرئيسية لتحسين الكفاءة وجودة المنتج

Introduction Thermoforming multi-station machines play a crucial role in the modern plastics processing industry. Their efficient production capabilities and wide range of applications make them the preferred choice for many companies. However, the performance and stability of the heating system directly impact the final product quality and production efficiency. This article will discuss common heating […]

نشا الذرة والمادة المركبة PP: تطبيق مبتكر في علب نشا الذرة القابلة للتحلل الحيوي

Corn Starch and PP Composite Material: Innovative Application in Biodegradable Corn Starch Boxes Introduction With the global awareness of environmental protection continuously increasing, reducing plastic pollution and promoting the use of biodegradable materials have become the focus of attention. The combination of corn starch and polypropylene (PP) in composite materials for corn starch boxes has […]

تعظيم الكفاءة والدقة: دور مناورات ماكينات التشكيل الحراري في التصنيع الحديث

Maximizing Efficiency and Precision: The Role of Thermoforming Machine Manipulators in Modern Manufacturing Introduction Thermoforming machines are equipment used to process plastic sheets into various shapes by heating, forming and cooling. In order to improve production efficiency and product quality, thermoforming machines are usually equipped with manipulators to automate handling, loading and unloading, and stacking. […]

التسخين الدقيق: السلاح السري في صناعة المنتجات البلاستيكية الحديثة

Precision Heating: The Secret Weapon of Modern Plastic Product Manufacturing Introduce In modern industrial production, thermoforming machines are the core equipment for plastic processing, and the choice of heating technology directly affects production efficiency and product quality. This article will explore the four-stage and five-stage heating technologies of thermoforming machines in depth to help you […]