What Is a Thermoforming Chain?

In the world of automated plastic packaging production, the thermoforming chain plays a silent yet critical role. Often overshadowed by heaters, molds, or vacuum systems, this chain system is the mechanical backbone that drives the continuous transport of plastic sheets through various processing stages of a thermoforming machine.

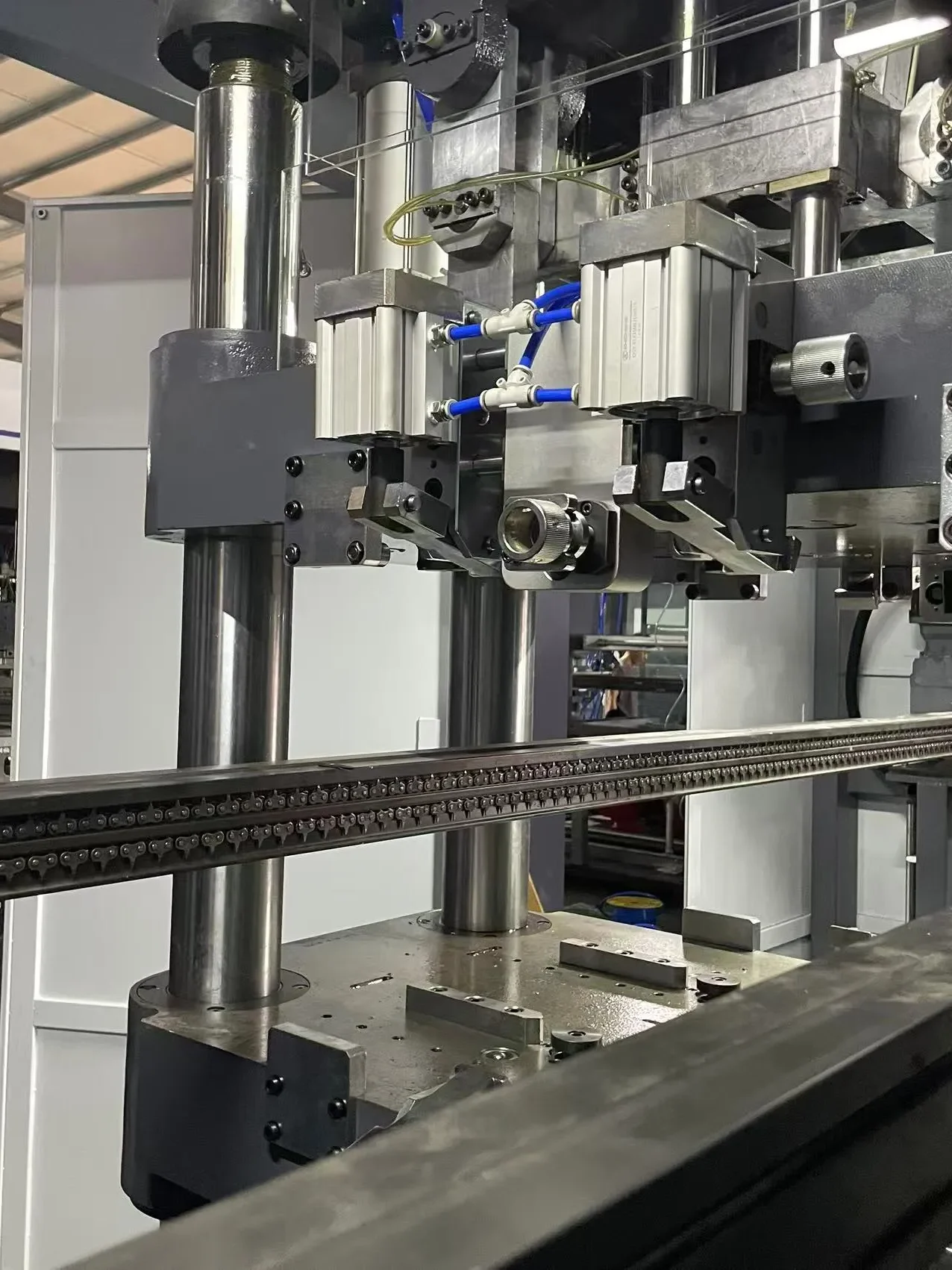

A thermoforming chain is a precision-engineered conveyor mechanism that securely grips and guides plastic sheets with perfect alignment and synchronized timing. It is especially vital in multi-station thermoforming machines, where forming, cutting, and stacking occur in separate, automated stations. In these high-speed setups, the chain’s reliability and accuracy are directly tied to production output, product consistency, and overall machine efficiency.

Whether you’re producing food containers, clamshell trays, PET lids, or medical packaging, the performance of your chain system can make or break your production line. The chain must withstand high temperatures, resist stretching, and maintain precise movement under continuous loads—all while ensuring minimal wear and tear on the machine.

In this article, we’ll dive into how thermoforming chains work, explore different chain types and materials, share maintenance best practices, and offer tips on selecting the right chain for your specific thermoforming setup—including multi-station machines. Understanding this component is key to minimizing downtime, improving forming precision, and optimizing long-term equipment performance.

Why Thermoforming Chains Matter in Thermoforming Equipment

In thermoforming systems—especially in multi-station thermoforming machines—the thermoforming chain is not just a mechanical accessory; it’s a mission-critical component that directly affects production efficiency, product consistency, and operational cost.

Here are real-world reasons why thermoforming chains matter:

1. Minimizing Material Waste

When the chain maintains perfect grip and alignment of the plastic sheet, it ensures each mold cavity is properly filled and formed. Misfeeds caused by chain slippage or wear can result in partial forming or cutting errors—leading to unnecessary material waste and scrap rates. Over time, this has a major cost impact, especially with high-grade materials like PET or PLA.

2. Reducing Machine Downtime

Chain failures—such as broken links, wear elongation, or misalignment—often require unplanned stops for replacement or re-tensioning. By choosing high-quality, heat-resistant chains and maintaining them properly, manufacturers can reduce unplanned downtime and keep production running smoothly.

3. Ensuring Forming Accuracy

In pressure or vacuum forming, even a 1–2 mm deviation in sheet position can result in poor forming quality or mismatched cuts. A precise chain ensures each sheet segment is positioned exactly where it needs to be—supporting repeatable, high-precision forming.

4. Supporting Automation

Modern thermoforming machines often use servo-driven index control and synchronization between forming, cutting, and stacking. A stable, tensioned chain system enables more accurate integration with PLCs, sensors, and motion controls—improving overall automation performance.

5. Lowering Maintenance Frequency

A well-designed and lubricated chain reduces wear on sprockets and chain tracks, minimizing the need for frequent part replacements or maintenance interventions. This leads to longer service intervals, lower labor costs, and greater machine availability.

6. Preventing Heat Deformation

Thermoforming chains operate close to heating elements, especially in sheet preheating zones. Low-grade chains often deform under high temperatures, causing feeding instability. Heat-resistant chains maintain shape and tension, ensuring stable sheet advance even during long production runs.

Types of Thermoforming Chains

Thermoforming chains come in various types, each designed to handle specific operational demands such as temperature resistance, tensile strength, and compatibility with forming materials. Choosing the right type of chain is essential for maintaining high performance, reducing downtime, and ensuring product consistency.

- 45Mn Steel Pin Chains with Grippers (Used by Our Company)

Our company uses high-strength 45Mn steel pin chains with grippers, specifically engineered for multi-station thermoforming machines such as the MS720×600, MS800×700, and MS900×700. These chains are built from 45 manganese steel, known for its superior hardness, durability, and wear resistance. The integrated grippers ensure precise sheet transport throughout the heating, forming, and cutting stations. This chain type excels in high-speed and high-temperature environments, making it ideal for long production cycles and continuous thermoforming operations. Its robust mechanical properties significantly reduce chain elongation and improve service life.

- Stainless Steel Chains

Often used in food-grade packaging lines or cleanroom environments, stainless steel thermoforming chains offer excellent corrosion resistance and hygiene benefits. However, they are generally less wear-resistant than manganese steel chains. - Roller Chains

These are simpler in design and typically used in low-speed or basic thermoforming setups. While cost-effective, they may not provide the precision needed for complex multi-station processes. - Precision Pitch Chains

Used in servo-driven systems or automated production lines, precision pitch chains reduce backlash and offer highly accurate positioning, suitable for forming intricate packaging products.

How Thermoforming Chains Work: Step-by-Step in a Production Cycle

Thermoforming chains play a critical role in the movement and positioning of plastic sheets during the entire thermoforming process. Especially in multi-station thermoforming machines, such as the ones used in our factory, the chains ensure continuous, synchronized sheet transport through each phase of the production cycle. Here’s a step-by-step breakdown of how thermoforming chains operate within a standard production line:

Step 1: Sheet Feeding

Plastic sheets (e.g., PET, PP, or PLA) are loaded onto the feeding unit. The thermoforming chain with grippers, such as our 45Mn steel chain, engages the edges of the sheet. The grippers ensure a firm hold, preventing slippage during high-speed operations.

Step 2: Heating Zone

As the sheet is pulled by the chain into the heating station, it moves through precisely controlled infrared heaters or ceramic elements. The chain must withstand high temperatures while maintaining tension and alignment. Our manganese steel chains are heat-treated for exactly this purpose, ensuring dimensional stability and smooth transport.

Step 3: Forming Station

Once the sheet reaches its optimal forming temperature, the chain indexes the material into the forming station. Here, molds press into the softened sheet to shape products such as cups, trays, or containers. Chain precision is crucial at this point—any misalignment can lead to product defects or wasted material.

Step 4: Cooling and Trimming

The formed parts are cooled and then transported by the chain to the trimming or cutting station. Chains must retain their grip and guide the sheet steadily through the cutting dies to ensure clean edges and consistent dimensions.

Step 5: Scrap Collection and Ejection

After cutting, the leftover skeleton is moved forward for scrap collection, while the finished products are ejected or stacked. The thermoforming chain continues to operate in synchronization with all moving components, completing the cycle and resetting for the next sheet.

Common Issues with Thermoforming Chains & How to Prevent Them

Thermoforming chains are essential components in any automated thermoforming line, especially in high-precision multi-station thermoforming machines. However, like any mechanical part under continuous stress, they are prone to wear and failure if not properly maintained. Below are the most common issues faced with thermoforming chains—along with effective ways to prevent costly breakdowns and unplanned downtime.

1. Chain Stretch and Elongation

Cause: Continuous exposure to high tension and heat can cause the metal links to stretch over time, resulting in inaccurate indexing and product misalignment.

Prevention:

Use high-strength materials such as 45Mn steel for better heat and load resistance.

Implement a tension monitoring system to detect abnormal slack early.

Replace chains before they exceed their maximum stretch limit (usually 3% of original length).

2. Gripper Malfunction or Misalignment

Cause: Debris, dust, or worn springs in the gripper mechanism can cause poor grip on the plastic sheet, leading to slipping or incomplete transport.

Prevention:

Regularly clean the grippers and inspect spring tension.

Use anti-dust covers or shields in high-contamination environments.

Replace individual grippers instead of the whole chain when wear is localized.

3. Chain Jamming or Breakage

Cause: Improper chain tension, foreign object interference, or overloading can cause the chain to jam or break suddenly.

Prevention:

Train operators to never override limit sensors or emergency stops.

Install chain guides and tensioners to maintain consistent alignment.

Always use chains designed for the specific machine size and load.

4. Thermal Fatigue and Corrosion

Cause: Continuous heating and cooling cycles can fatigue the metal, and in humid environments, corrosion may occur—especially on untreated chains.

Prevention:

Use heat-treated, corrosion-resistant chains, like the 45Mn steel chains used in our production line.

Store spare chains in dry, climate-controlled environments.

Inspect chains during scheduled maintenance for signs of discoloration or rust.

How to Maintain Thermoforming Chains: Best Practices

Regular maintenance of thermoforming chains is essential for keeping your multi-station thermoforming machines running smoothly and efficiently. Chains that are not properly maintained can lead to production interruptions, misaligned sheets, increased wear on machine components, and product defects. Below are proven best practices to extend the lifespan of your thermoforming chains and ensure consistent performance.

1. Set a Routine Maintenance Schedule

Creating a maintenance calendar tailored to your production intensity is the first step. Include daily visual inspections, weekly cleaning, and monthly lubrication. For high-output lines, inspect the chains after every shift.

Tip: Use a checklist for operators and maintenance staff to ensure nothing is overlooked.

2. Lubricate Properly—And Regularly

Thermoforming chains operate under high temperatures and friction. Proper lubrication is vital to reduce wear on pins, bushings, and grippers.

Apply lubricant only to clean, dry chains—never on hot, contaminated surfaces.

Avoid over-lubrication to prevent residue buildup that attracts dust.

3. Keep Chains Clean

Dust, debris, and plastic residue can accumulate quickly, especially in forming and trimming zones. Build-up can interfere with gripper function and chain movement.

Clean chains with a soft brush or compressed air daily.

Use mild degreasers when heavy build-up occurs—avoid water-based cleaners that can cause rusting.

4. Monitor Chain Tension

Improper tension can lead to chain jumping, poor sheet feeding, and excessive wear.

Use built-in chain tensioners or manual gauges to check and adjust tension regularly.

Maintain even tension across the full length to avoid localized stress or misalignment.

5. Inspect for Wear and Damage

Routine inspection helps catch early signs of fatigue before failure occurs.

Look for stretched links, damaged grippers, worn pins, or loose fasteners.

Replace damaged chain sections promptly—waiting too long can lead to full system downtime.

6. Keep Spare Chains and Parts in Stock

Delays in replacing a worn or broken chain can be costly. Stock essential spares like:

Extra chain links and grippers

Replacement pins and bushings

Full backup chains (especially for high-use machines)

7. Train Operators and Maintenance Teams

Even the best maintenance plan fails without proper execution. Train your staff on:

Daily visual checks

Recognizing signs of chain failure

Lubrication and cleaning procedures

Chain installation and removal

Our Chain Solutions: Reliable & Durable Thermoforming Chains

At MingSu Machinery, we understand that a reliable thermoforming chain is the backbone of efficient production. That’s why we offer high-performance 45Mn steel thermoforming chains, specifically engineered for the high-speed, high-precision demands of multi-station thermoforming machines.

Precision-Engineered for Performance

Our chains are crafted from 45Mn high-strength steel, known for its superior tensile strength, wear resistance, and heat tolerance. Each component is heat-treated to ensure durability under continuous high-temperature operation, especially in demanding environments like food packaging or medical tray production.

Gripper-Style Chain for Sheet Stability

We use a gripper-style thermoforming chain, ideal for securely holding and guiding plastic sheets through every station—forming, cutting, stacking—with high accuracy. This ensures:

Consistent sheet tension

No slippage or misalignment

Flawless forming quality, even at high speeds

Built to Reduce Downtime

Our chains are designed with easy-access grippers, making them quick to install, maintain, or replace. With proper lubrication and routine maintenance, they deliver extended service life and help avoid unplanned machine stops.

Trusted by Manufacturers Worldwide

Whether you’re producing PET clamshells, PP trays, or PLA cup lids, our thermoforming chains are the trusted solution behind consistent, high-speed output. Many of our customers report a 30–40% increase in uptime after switching to our chain systems.

Conclusión

While often overlooked, the thermoforming chain is one of the most essential components in any multi-station thermoforming machine. Its precision, durability, and stability directly influence product quality, material yield, automation accuracy, and long-term operational efficiency. From ensuring perfectly aligned sheet transport to resisting thermal fatigue during high-speed runs, a high-quality chain—like our 45Mn steel pin chain with grippers—makes a measurable difference in every production cycle.

By selecting the right chain type, implementing proactive maintenance practices, and understanding its role in the forming process, manufacturers can significantly reduce downtime, lower scrap rates, and enhance their overall production capability. In short, mastering your thermoforming chain is not just about keeping things moving—it’s about keeping your business ahead.