Thermoforming Machines for Packaging: Innovations and Trends

In the dynamic world of packaging, thermoforming machines play a crucial role in shaping the way products are presented, protected, and delivered to consumers. As consumer preferences evolve and sustainability becomes a top priority, the packaging industry is witnessing rapid advancements and innovative trends. In this article, we delve into the latest innovations and trends in thermoforming machines for packaging, exploring how these technologies are reshaping the landscape of the packaging industry.

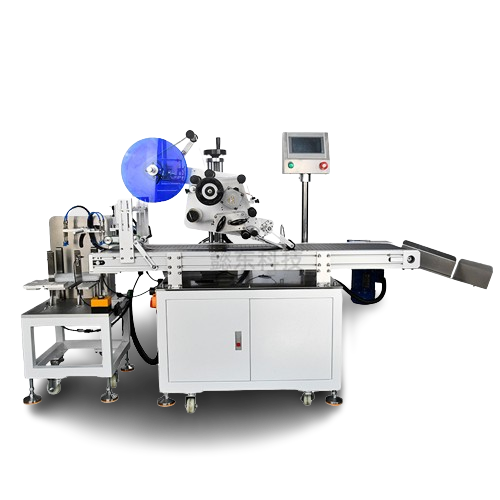

Introduction to Thermoforming Machines for Packaging

Thermoforming is a versatile manufacturing process that involves heating a plastic sheet to a pliable temperature, forming it into a specific shape using a mold, and then trimming it to create a finished product. Thermoforming machines for packaging are utilized across various industries to produce a wide range of packaging solutions, including trays, clamshells, blister packs, and containers.

Innovations in Thermoforming Machine Technology

1. Advanced Material Handling Systems

Modern thermoforming machines are equipped with advanced material handling systems that streamline the packaging process. Automated loading and unloading systems, robotic arms, and conveyor belts ensure efficient material handling, minimizing downtime and maximizing productivity.

2. Intelligent Control Systems

Intelligent control systems are revolutionizing thermoforming machine operation, offering precise control over heating, forming, and trimming processes. Programmable logic controllers (PLCs) and human-machine interfaces (HMIs) enable operators to monitor and adjust machine parameters in real-time, ensuring consistent product quality and reducing waste.

3. Sustainable Packaging Solutions

With increasing emphasis on sustainability, thermoforming machines are being designed to accommodate eco-friendly materials and processes. From biodegradable plastics to recycled materials, manufacturers are incorporating sustainable practices into their packaging solutions, aligning with consumer preferences for environmentally responsible products.

4. High-Speed Production

Advancements in thermoforming technology have led to the development of high-speed machines capable of producing large volumes of packaging in a shorter timeframe. Increased automation, improved mold design, and optimized process parameters enable rapid production without compromising quality.

Trends Shaping the Future of Thermoforming Machines for Packaging

1. Customization and Personalization

Customization and personalization are emerging trends in packaging, driven by the desire to create unique and memorable consumer experiences. Thermoforming machines are being equipped with modular components and flexible designs, allowing manufacturers to tailor packaging solutions to specific product requirements and branding strategies.

2. Intelligent Packaging Solutions

The integration of smart technologies such as RFID tags, NFC sensors, and QR codes into packaging is transforming the way products are tracked, traced, and interacted with throughout the supply chain. Thermoforming machines are adapting to accommodate these intelligent packaging solutions, enabling enhanced functionality and communication between products and consumers.

3. Multi-material Packaging

As packaging designs become more complex and diverse, thermoforming machines are being engineered to handle a wider range of materials, including composites and laminates. Multi-material packaging offers improved barrier properties, enhanced aesthetics, and greater product protection, catering to the diverse needs of different industries and applications.

4. Integration with Industry 4.0 Technologies

Thermoforming machines are increasingly being integrated with Industry 4.0 technologies such as artificial intelligence, cloud computing, and predictive analytics. This integration enables remote monitoring, predictive maintenance, and data-driven optimization, enhancing machine efficiency, reliability, and overall performance.

Case Studies: Successful Applications of Thermoforming Machines in Packaging

Case Study 1: Food Packaging

A food packaging company implemented a state-of-the-art thermoforming machine equipped with advanced material handling systems and intelligent control systems. The machine enabled the company to produce customized packaging solutions with superior barrier properties and extended shelf life, meeting the demands of both retailers and consumers for fresh and sustainable packaging.

Case Study 2: Pharmaceutical Packaging

A pharmaceutical company adopted a thermoforming machine capable of producing blister packs with RFID-enabled tracking capabilities. The machine integrated RFID technology into the packaging, allowing the company to track individual units throughout the supply chain, ensure product authenticity, and comply with regulatory requirements for traceability and serialization.

สรุป

Thermoforming machines continue to evolve and innovate, driving advancements in packaging technology and meeting the ever-changing demands of the industry. From advanced material handling systems to intelligent control systems and sustainable packaging solutions, these machines are at the forefront of packaging innovation.

As customization, sustainability, and smart packaging become increasingly important, thermoforming machines are adapting to meet these challenges, enabling manufacturers to create packaging solutions that are not only functional and cost-effective but also environmentally friendly and consumer-centric. Looking ahead, the future of thermoforming machines for packaging promises to be exciting and transformative, reshaping the way products are packaged, presented, and experienced by consumers worldwide.