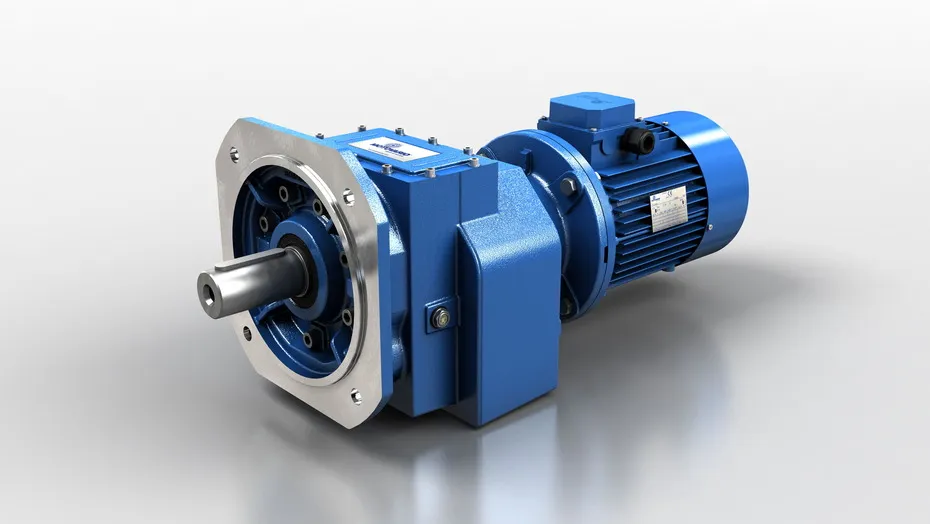

Understanding Reduction Gears and Their Importance in Thermoforming Machines: A Comprehensive Guide

What is a Reduction Gear? A reduction gear, also known as a gear reducer or gearbox, is a crucial mechanical component used to reduce the rotational speed of a motor or engine while simultaneously increasing the torque output. This process is essential in various industrial applications, including thermoforming machines, where precise control over speed and […]

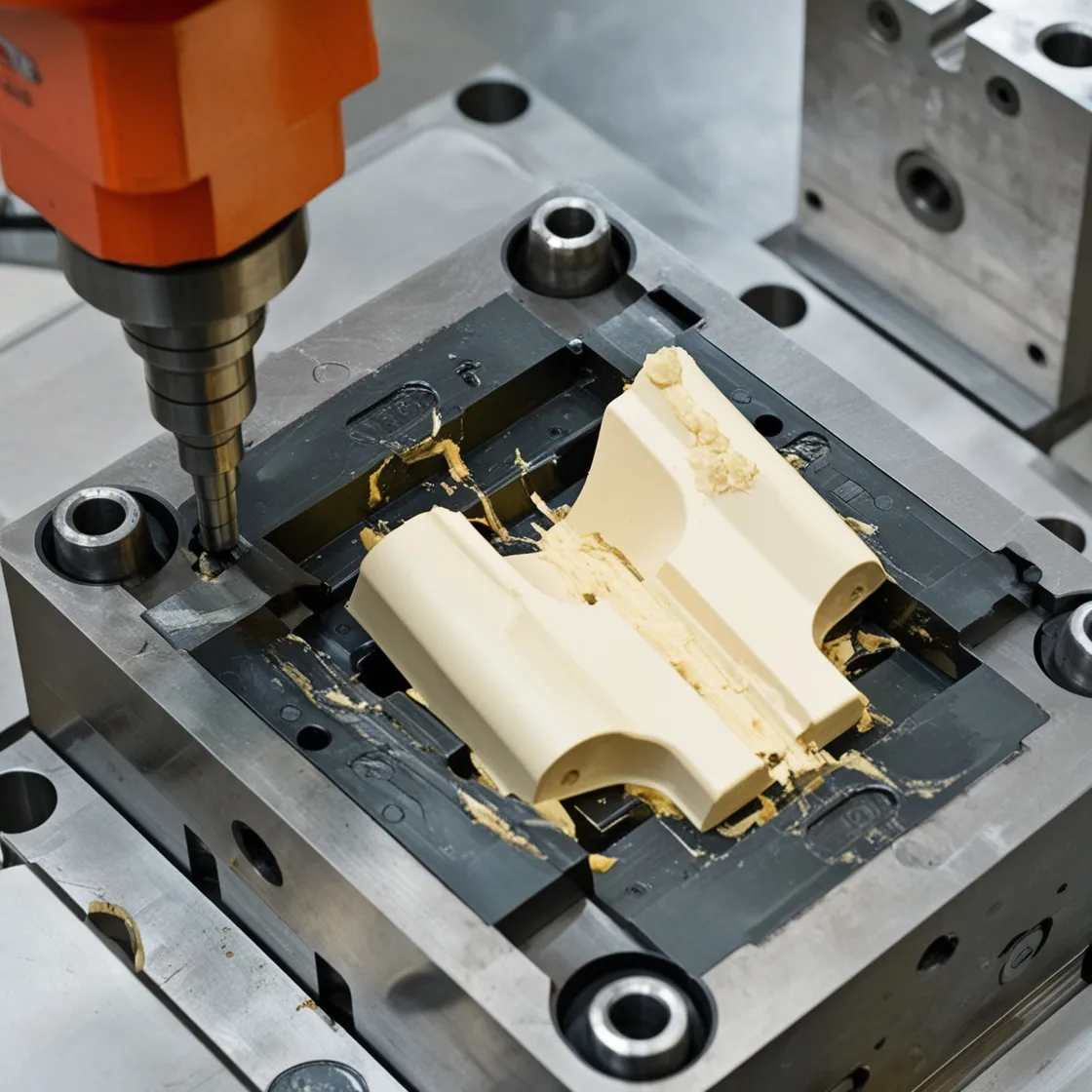

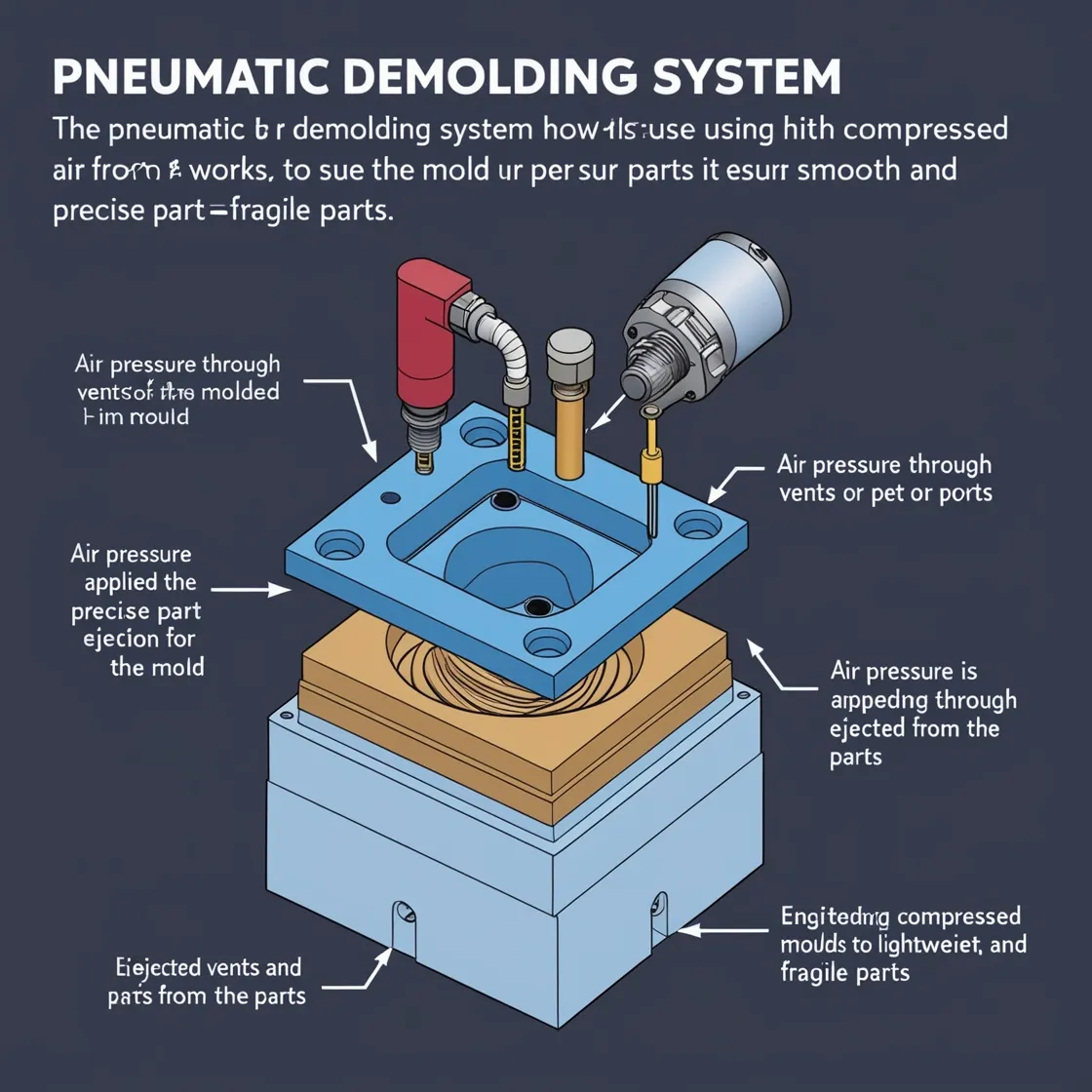

How to Overcome Demolding Issues: Best Practices and Latest Technological Advancements

Common Challenges in Demolding While demolding systems bring significant benefits, they also encounter challenges that can affect production efficiency and product quality. Below are some of the typical issues faced during the demolding process: Sticking Parts:Adhesion between the mold and the molded product is a frequent problem, often caused by inadequate cooling or flaws in […]

The Ultimate Guide to Thermoforming Demolding Systems: Types, Functions, and Key Benefits

Introduction Demolding systems are essential for ensuring both the efficiency and accuracy of thermoforming machines. These systems are designed to remove formed products from molds in a safe and consistent manner, which helps to minimize defects, reduce downtime, and boost production speed. As the thermoforming industry continues to evolve, the development of advanced demolding technologies […]

Comprehensive Guide to Circuit Board Troubleshooting: Step-by-Step Instructions, Voltage Management, and Repair Techniques

Circuit boards are at the core of modern technology, driving everything from household gadgets like smartphones and microwaves to advanced industrial systems such as automated machinery and medical equipment. Despite their reliability, their intricate design makes them susceptible to occasional malfunctions. Physical damage, voltage fluctuations, or component failures can disrupt operations, causing costly downtime. Efficient […]

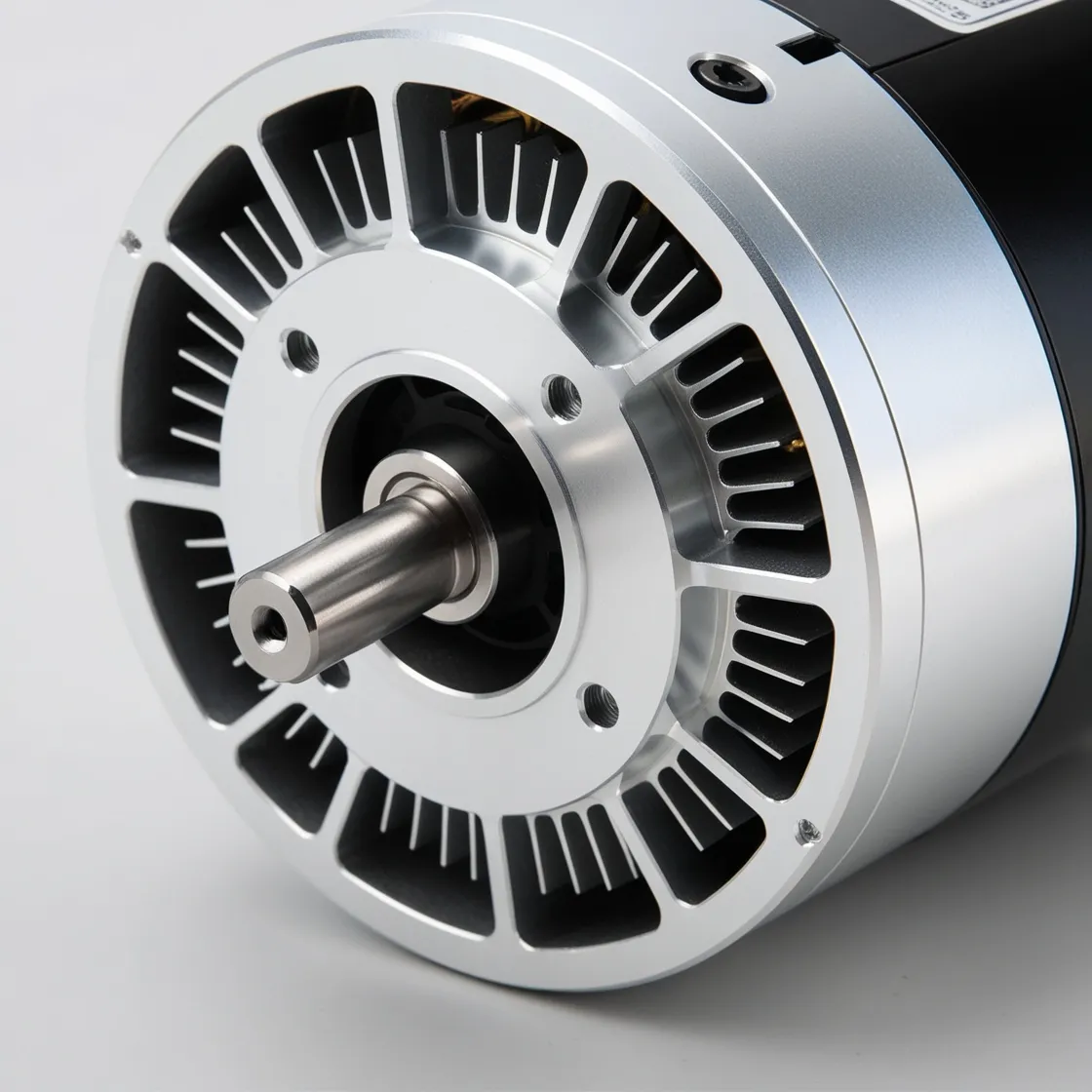

Servo Motors Explained: Key Components, Function & Benefits

Servo motors are crucial in modern automation and robotics, providing precision control over positioning, speed, and torque. Whether you’re in industrial automation or working with complex robotics, understanding servo motors and their operational principles can greatly enhance your ability to integrate them effectively. This guide explores servo motor components, the working mechanism, types, and significant […]

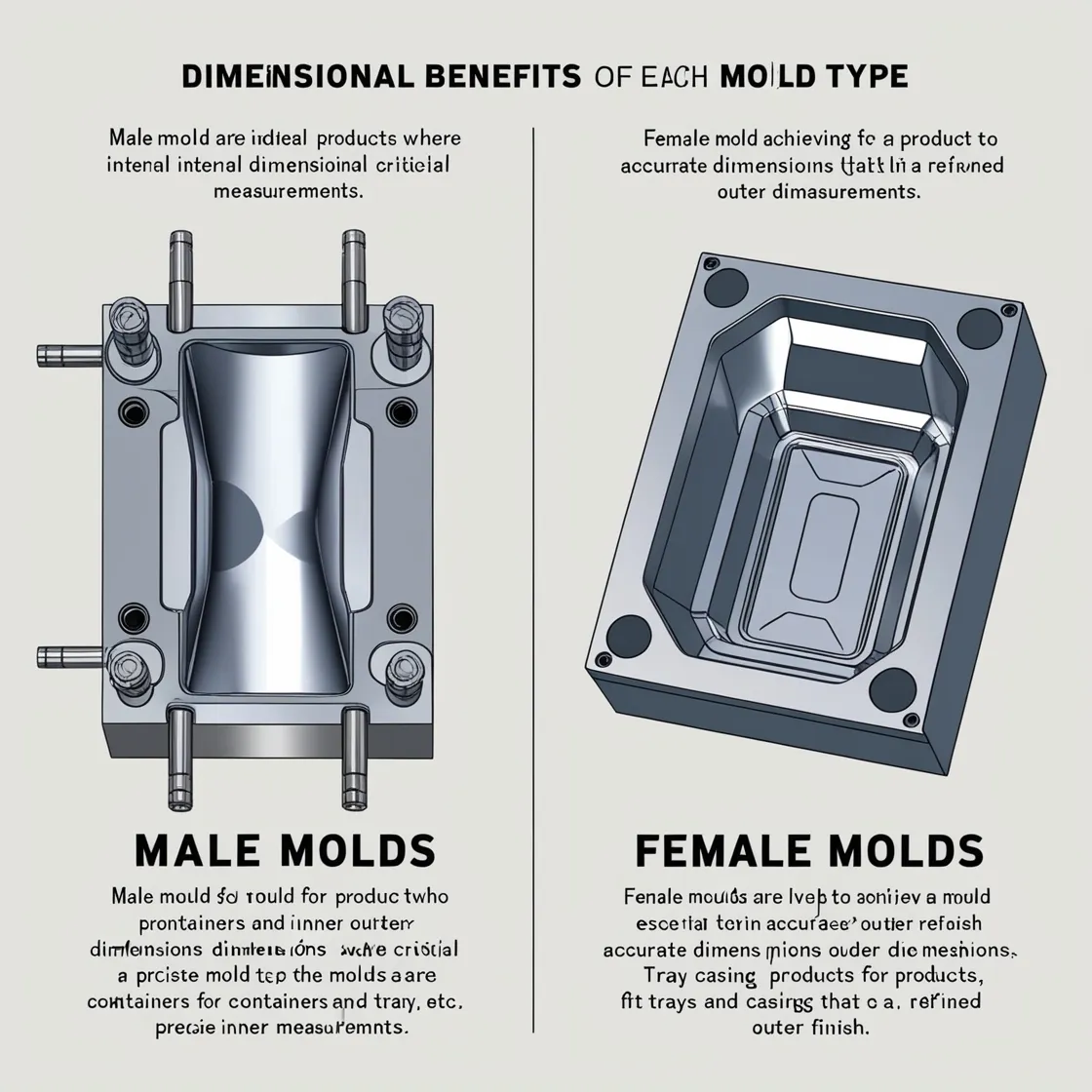

Choosing Between Positive and Negative Molds in Thermoforming: Key Considerations for Precision Manufacturing.

In thermoforming, mold selection is central to achieving desired product quality, precision, and manufacturing efficiency. The two primary types of molds—male (positive) and female (negative) molds—each impart unique benefits and limitations, making them suited to specific applications within thermoforming. This guide provides an in-depth comparison of these molds to help manufacturers optimize their process and […]

Top Features to Look for in a Thermoforming Control Panel Display

Choosing the right thermoforming control panel is crucial for ensuring efficient, safe, and precise operation in modern manufacturing environments. From user-friendly interfaces to real-time monitoring, a high-quality thermoforming control panel display can significantly enhance productivity and minimize downtime. This guide covers the most important features to consider, explains how they can impact production, and explores […]

How Thermoforming Cooling Systems Operate

How Thermoforming Cooling Systems Operate Thermoforming involves shaping a heated thermoplastic sheet over a mould. The process relies heavily on energy, with the heating system consuming more than 70% of the energy requirement. Basic principles of thermoforming include heating, moulding, and cooling. Cooling plays a vital role in solidifying the formed sheet, ensuring product quality and integrity. […]

Optimizing Thermoformed Part Quality with Vacuum Pump Technology: A Comprehensive Guide

Optimizing Thermoformed Part Quality with Vacuum Pump Technology: A Comprehensive Guide Thermoforming remains a crucial process in manufacturing, shaping plastic sheets into precise forms. This method is highly significant due to its efficiency and versatility. The global market for thermoformed plastics is anticipated to expand considerably, reaching approximately USD 74.12 billion by 2034. Vacuum pumps […]