Automatic Mold Alignment System in Thermoforming Machines: Boosting Precision and Efficiency

Introduction: What Is an Automatic Mold Alignment System In the competitive landscape of plastic packaging manufacturing, achieving high productivity while maintaining consistent quality is the ultimate goal. One of the key enablers of this balance in thermoforming multi-station machines is the automatic mold alignment system. An automatic mold alignment system is a precision automation solution that […]

Thermoforming Cylinder Guide: How Pneumatic Systems Enhance Positive and Negative Pressure Forming Machines

In the plastic packaging industry, positive and negative pressure thermoforming machines are widely used for producing disposable food containers, blister trays, folding boxes, and other products due to their high efficiency and precise forming capabilities. In such equipment, cylinders act as critical actuators whose performance directly impacts forming quality, motion stability, and production efficiency. This article […]

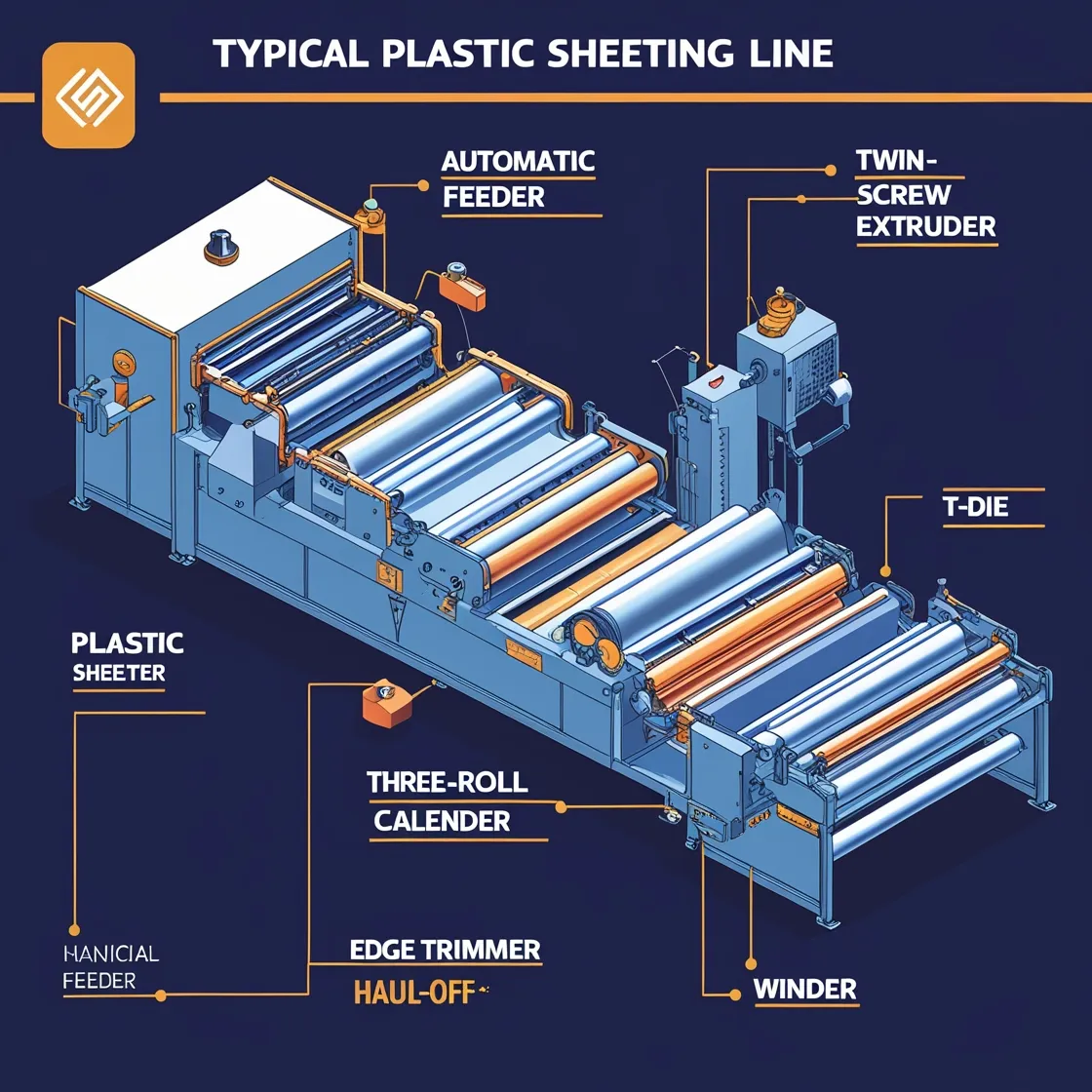

Plastic Sheeting Machine: Complete Guide to Sheet Extrusion and Industrial Applications

Introduction The plastic sheeting machine is one of the most essential and widely used pieces of equipment in the modern plastic processing industry. Its primary function is to convert granular or pelletized plastic raw materials into continuous sheet products, which serve as foundational materials across a variety of industries. From food packaging and electronic device casings […]

Thermoforming Chain: Key Component for Multi-Station Thermoforming Machines

What Is a Thermoforming Chain? In the world of automated plastic packaging production, the thermoforming chain plays a silent yet critical role. Often overshadowed by heaters, molds, or vacuum systems, this chain system is the mechanical backbone that drives the continuous transport of plastic sheets through various processing stages of a thermoforming machine. A thermoforming chain is […]

Shantou Mingsu Machinery Impresses at CHINAPLAS 2025 with Live Demo of MS7260 Three-Station Thermoforming Machine

From April 15th to 18th, 2025, Shantou Mingsu Machinery Co., Ltd. proudly exhibited at CHINAPLAS 2025, held at the Shenzhen World Exhibition & Convention Center. As Asia’s premier plastics and rubber exhibition, the event brought together global leaders and innovators — and Mingsu stood out with real-time performance, smart technology, and strong customer engagement. MS7260 […]

Essential Thermoforming Machine Maintenance Guide: Tips for Servo Motors, Mold Clamping, and Pressure Systems

Maintaining your thermoforming machine is essential to ensure long-term efficiency and optimal performance. While common components like heating elements and vacuum systems often get the most attention, other key parts also need regular care to prevent breakdowns and maintain product quality. This guide covers the most important components, offering maintenance tips to help you extend […]

The Ultimate Guide to Maintaining Your Multi-Station Thermoforming Machine

Running a multi-station thermoforming machine involves much more than just setting it up and turning it on. If you want to get the most out of your machine and ensure consistent, high-quality production, you’ll need to stay on top of its maintenance. Proper care can extend the life of your machine, improve product quality, and […]

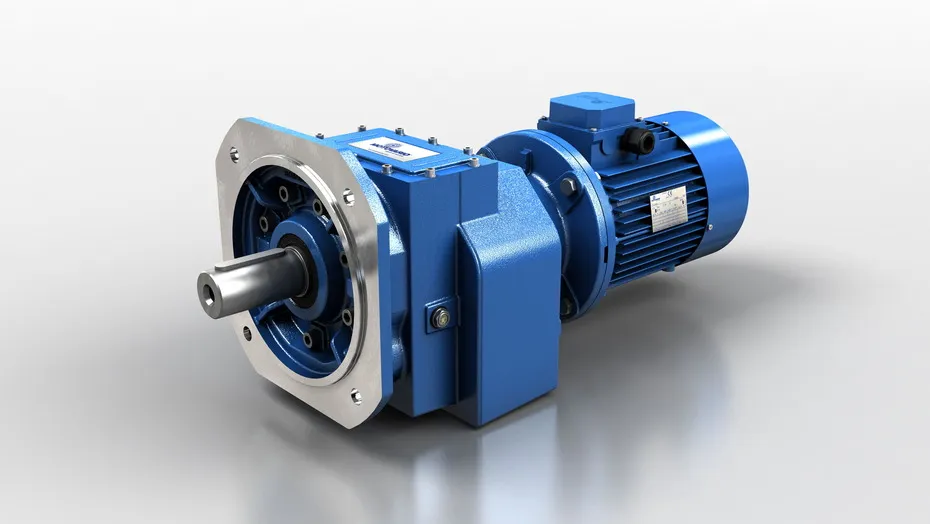

Understanding Reduction Gears and Their Importance in Thermoforming Machines: A Comprehensive Guide

What is a Reduction Gear? A reduction gear, also known as a gear reducer or gearbox, is a crucial mechanical component used to reduce the rotational speed of a motor or engine while simultaneously increasing the torque output. This process is essential in various industrial applications, including thermoforming machines, where precise control over speed and […]

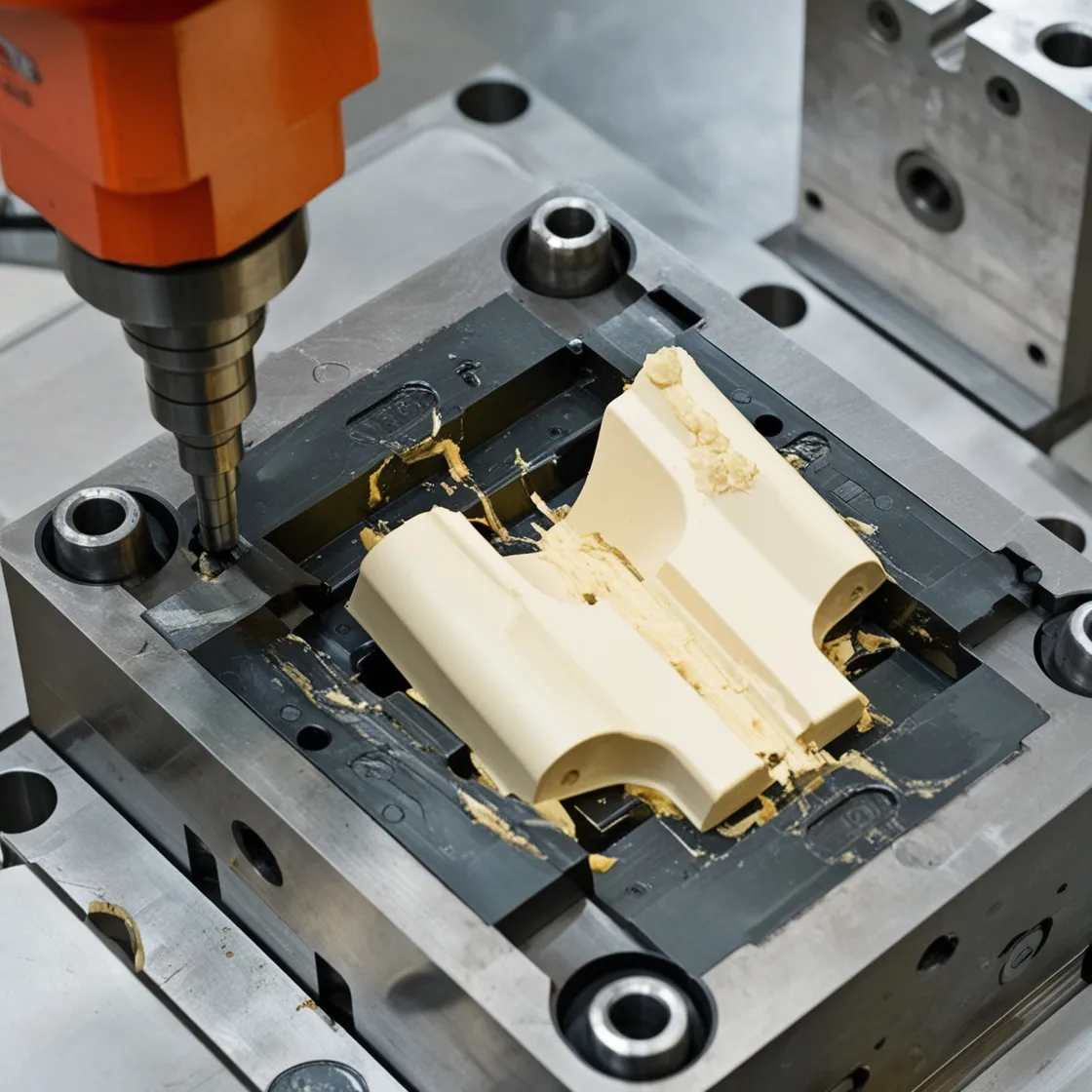

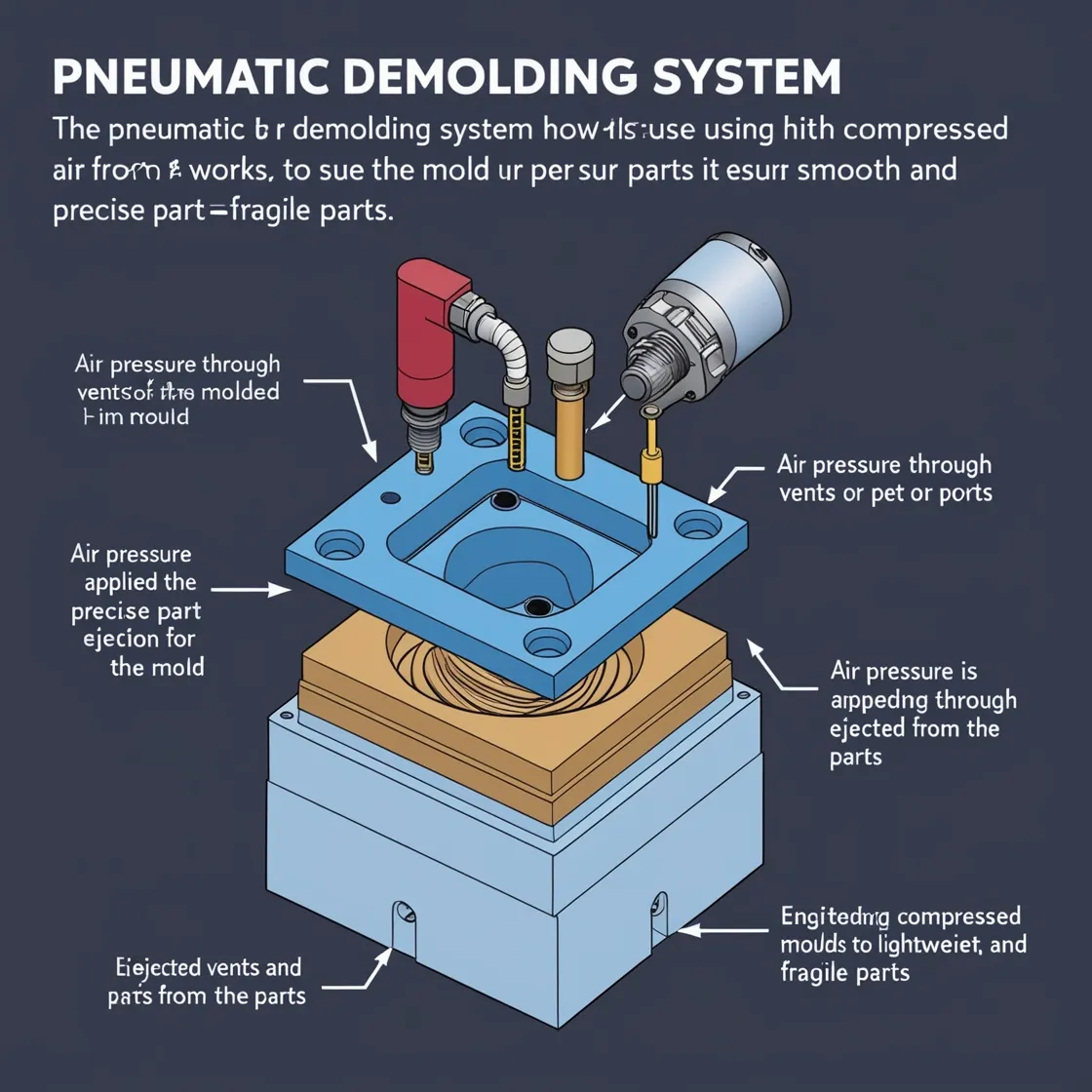

How to Overcome Demolding Issues: Best Practices and Latest Technological Advancements

Common Challenges in Demolding While demolding systems bring significant benefits, they also encounter challenges that can affect production efficiency and product quality. Below are some of the typical issues faced during the demolding process: Sticking Parts:Adhesion between the mold and the molded product is a frequent problem, often caused by inadequate cooling or flaws in […]

The Ultimate Guide to Thermoforming Demolding Systems: Types, Functions, and Key Benefits

Introduction Demolding systems are essential for ensuring both the efficiency and accuracy of thermoforming machines. These systems are designed to remove formed products from molds in a safe and consistent manner, which helps to minimize defects, reduce downtime, and boost production speed. As the thermoforming industry continues to evolve, the development of advanced demolding technologies […]