Inside Mesoforming: Precision Meets Efficiency

Take a virtual journey through our 20,000 sqm facility. Experience fully servo systems and 0.1mm molding accuracy that guarantees a 30% efficiency boost.

German-Standard Engineering

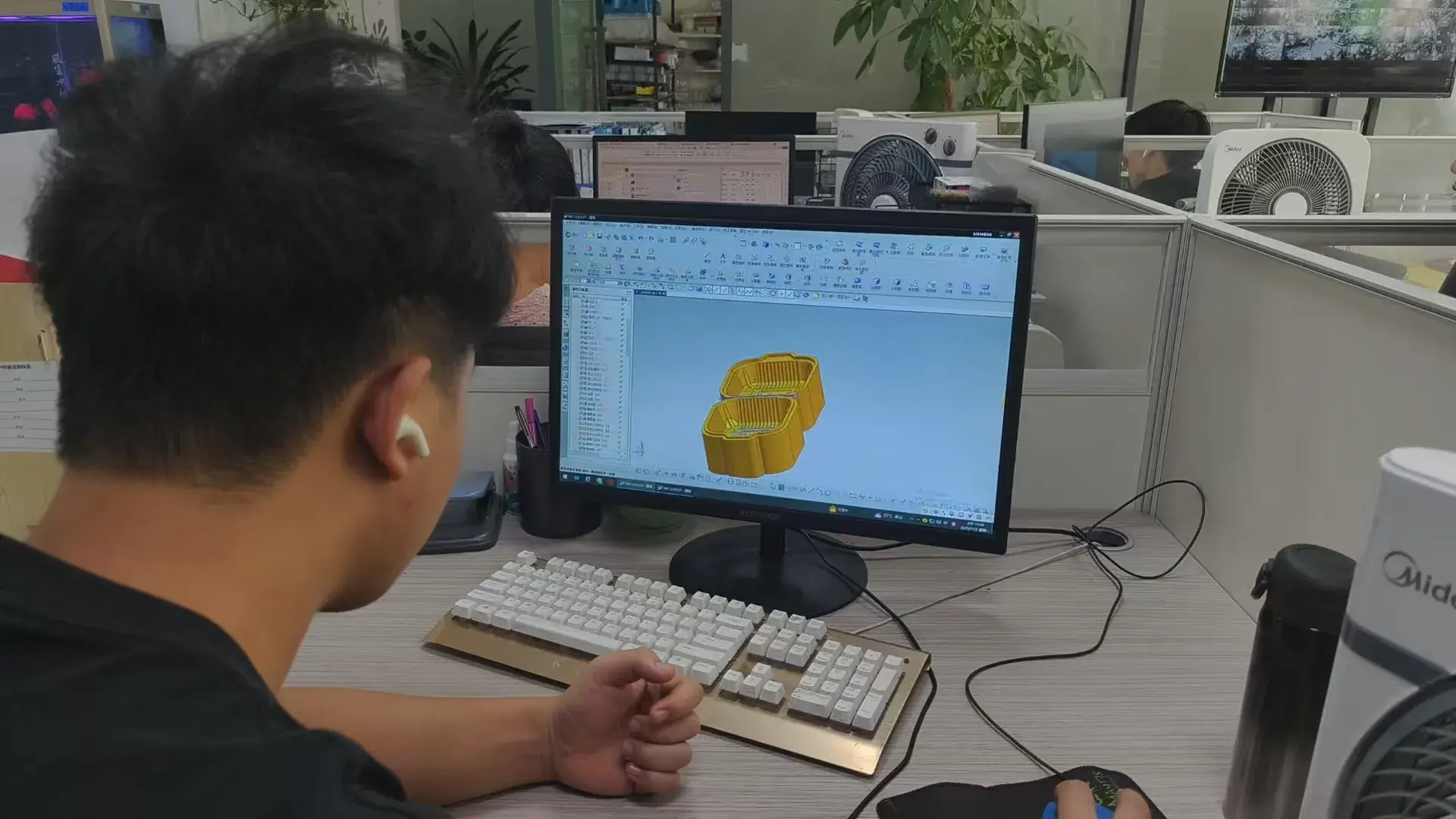

"Innovation starts before the metal is cut."

We utilize 100% 3D SolidWorks simulation for every machine. This digital twin technology allows us to stress-test components virtually, ensuring zero design defects before manufacturing begins.

- Finite Element Analysis (FEA)

- Custom Modular Design

- Servo Drive Optimization

Premium Steel Selection

We start with certified high-strength steel. Every frame undergoes a strict annealing process to eliminate internal stress, ensuring the machine structure remains undeformed for 20 years.

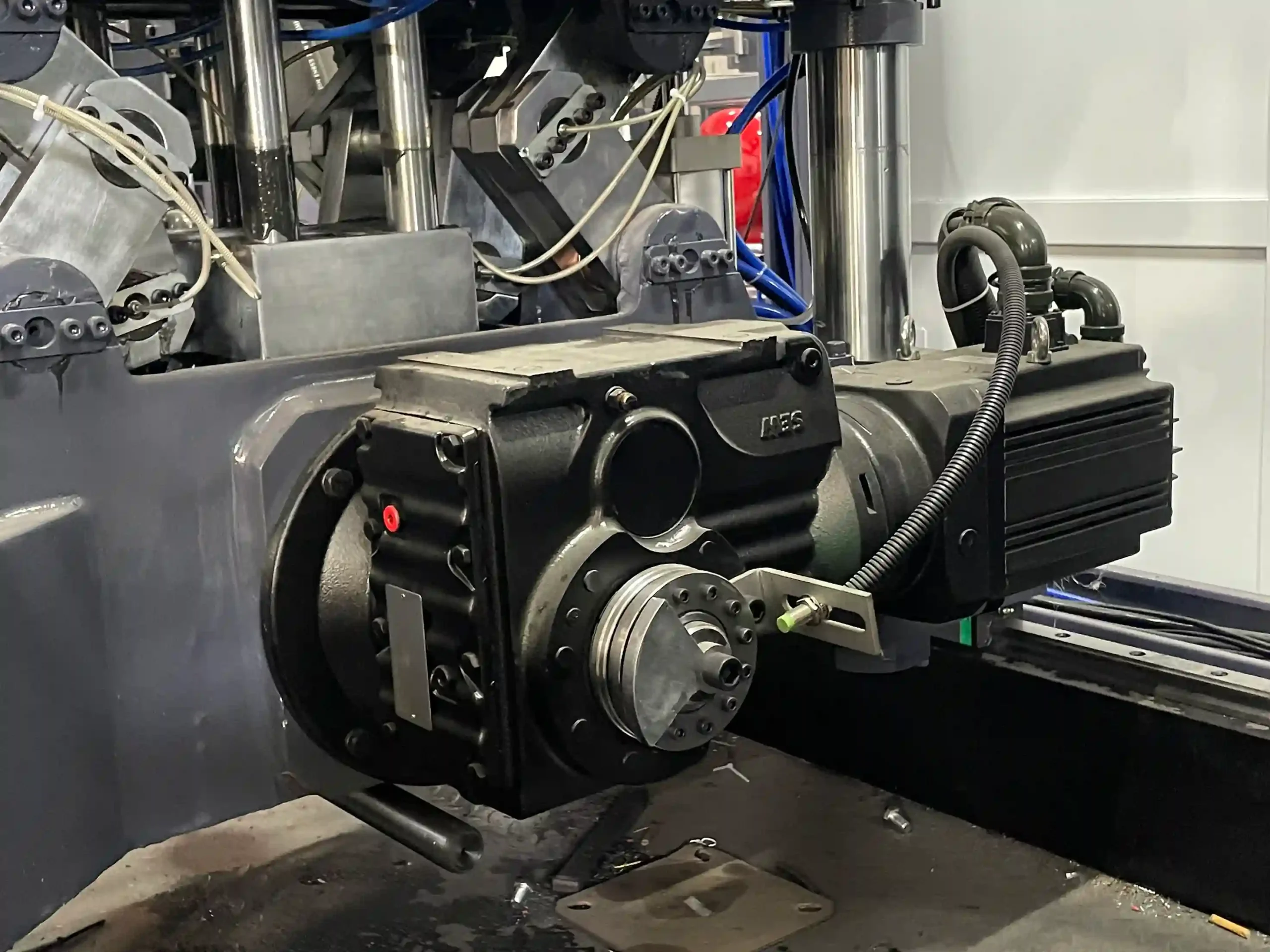

CNC Machining Center

0.1mm Accuracy Standard.

We don't outsource core components. All molds and critical parts are machined in-house using 5-Axis CNC centers, keeping tolerances within ±0.05mm.

SOP-Driven Assembly

Standardized Operating Procedures drive our assembly line. From cabling to screw tightening torque, every step is documented to eliminate human error.

The 5-Stage Quality Firewall

IQC

Incoming Quality Control. Siemens/Omron parts verification.

Process Check

Real-time dimensional inspection during machining.

Precision

CMM 3D scanning of mold surfaces.

Dry Run

72-Hour non-stop high-speed simulation.

FAT

Final Acceptance Test with finished product samples.

"We create problems in the factory so you face none in production."

Arrives in Perfect Condition

Vacuum Sealed Protection

Before packing, every machine is sprayed with anti-rust oil and wrapped in industrial vacuum aluminum foil. This guarantees 100% isolation from sea salt mist during the month-long ocean voyage.

5-Ton Load Bearing Crates

We use reinforced, fumigation-free plywood cases compliant with global customs standards. The base is thickened to withstand forklifts and heavy stacking loads.

Zero Movement Loading

Calculated loading positions ensure weight balance. We use steel wire ropes and wooden blocks to fix the machine inside the container, ensuring zero displacement.

Seeing is Believing.

Can't visit China right now? Schedule a 1-on-1 WhatsApp video tour. We will walk you through the factory floor in real-time.