Technology

TechnologyRevolutionizing Production: How Fully Servo Systems Boost Efficiency By 30%

Discover how replacing pneumatic systems with Mesoforming's advanced servo technology can drastically reduce energy consumption.

Discover our cutting-edge thermoforming solutions with precision engineering, energy efficiency, and industry-leading automation for superior product quality.

Tailor-made thermoforming machines designed to meet your specific production requirements with flexible configurations and scalable options.

Comprehensive technical support and after-sales service with 24/7 assistance, spare parts availability, and expert troubleshooting worldwide.

We are a factory. Since 2001, our machines have been exported to more than 80 countries worldwide.

Our professional QC department ensures every product's quality.

Warranty Policy: 13 months from the date of shipment.

Within the warranty period (excluding human factors), spare parts are repaired or replaced free of charge. After the warranty expires, the buyer only needs to cover the spare parts and shipping costs.

We will send our technicians to your factory for installation and operator training.

You are responsible for all related costs, including visa fees, round-trip air tickets, hotel accommodation, meals, and technician wages.

Positive and negative pressure thermoforming uses both positive and negative pressure simultaneously under controlled temperature.

Pressure from above (positive) and suction from below (negative) shape the thermoplastic material precisely.

Negative pressure thermoforming only uses vacuum suction from below, without pressure from above.

Thermoforming machines are widely used in packaging, trays, disposable containers, and more.

They feature high efficiency, uniform heating, and stable forming quality.

Water ripples: Related to film production speed.

Bubbles: Caused by high sheet temperature, air infiltration, or mixed materials.

Check sheet quality carefully before use.

Follow these steps for optimal machine operation:

Temperature settings vary by material:

Always refer to material specifications and conduct test runs. Factors affecting temperature settings include material thickness, ambient temperature, and desired forming quality.

Proper material handling ensures consistent quality:

Maintain product quality through continuous monitoring:

Follow this maintenance schedule for optimal performance:

Daily Maintenance:

Weekly Maintenance:

Monthly Maintenance:

Quarterly Maintenance:

Keep these parts in stock for minimal downtime:

Heating System:

Vacuum System:

Electrical Components:

Mechanical Components:

Control System:

Quick reference for common problems:

Heating Issues:

Forming Issues:

Mechanical Issues:

Our comprehensive support services include:

Increase production efficiency with these tips:

Process Optimization:

Material Management:

Equipment Optimization:

Operator Training:

Reduce material waste and improve sustainability:

Design Optimization:

Process Improvements:

Material Selection:

Quality Control:

Reduce energy consumption and costs:

Heating System:

Machine Operation:

Facility Management:

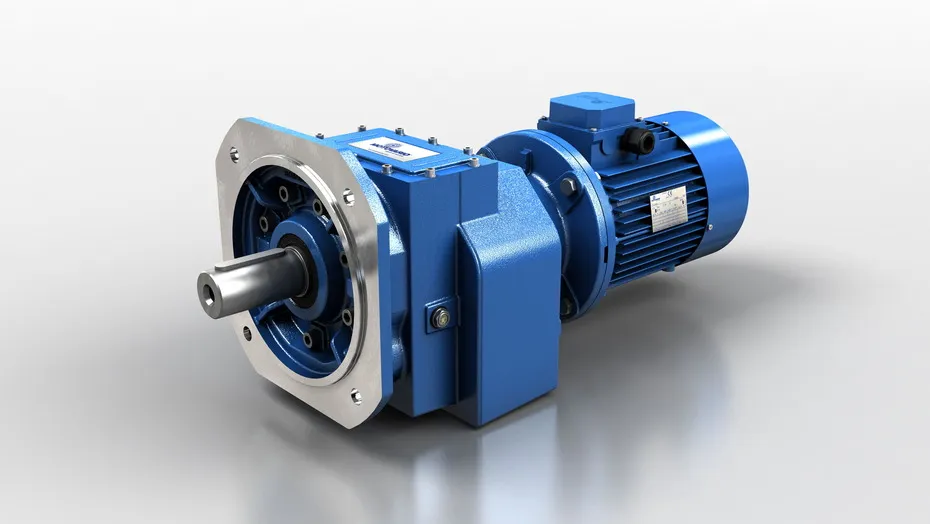

We offer various customization options:

Standard Sizes:

Heating Systems:

Automation Level:

Control Systems:

Special Features:

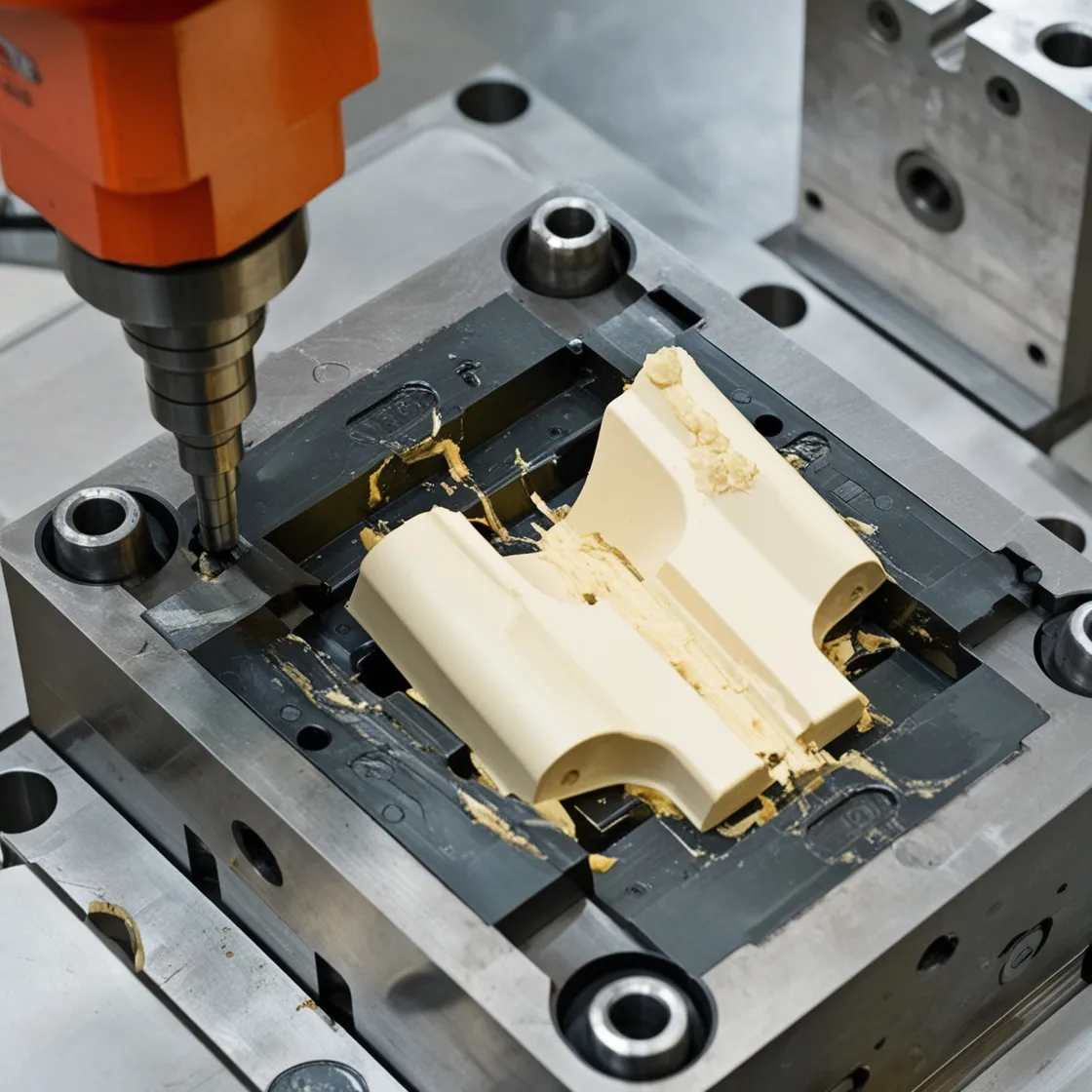

Choose from various mold and tooling solutions:

Mold Materials:

Mold Design:

Cutting Systems:

Additional Tooling:

Custom integration solutions for your production needs:

Material Handling:

Quality Systems:

Factory Integration:

Explore our latest innovations, exhibition updates, and expert guides on thermoforming technology.

Technology

TechnologyDiscover how replacing pneumatic systems with Mesoforming's advanced servo technology can drastically reduce energy consumption.

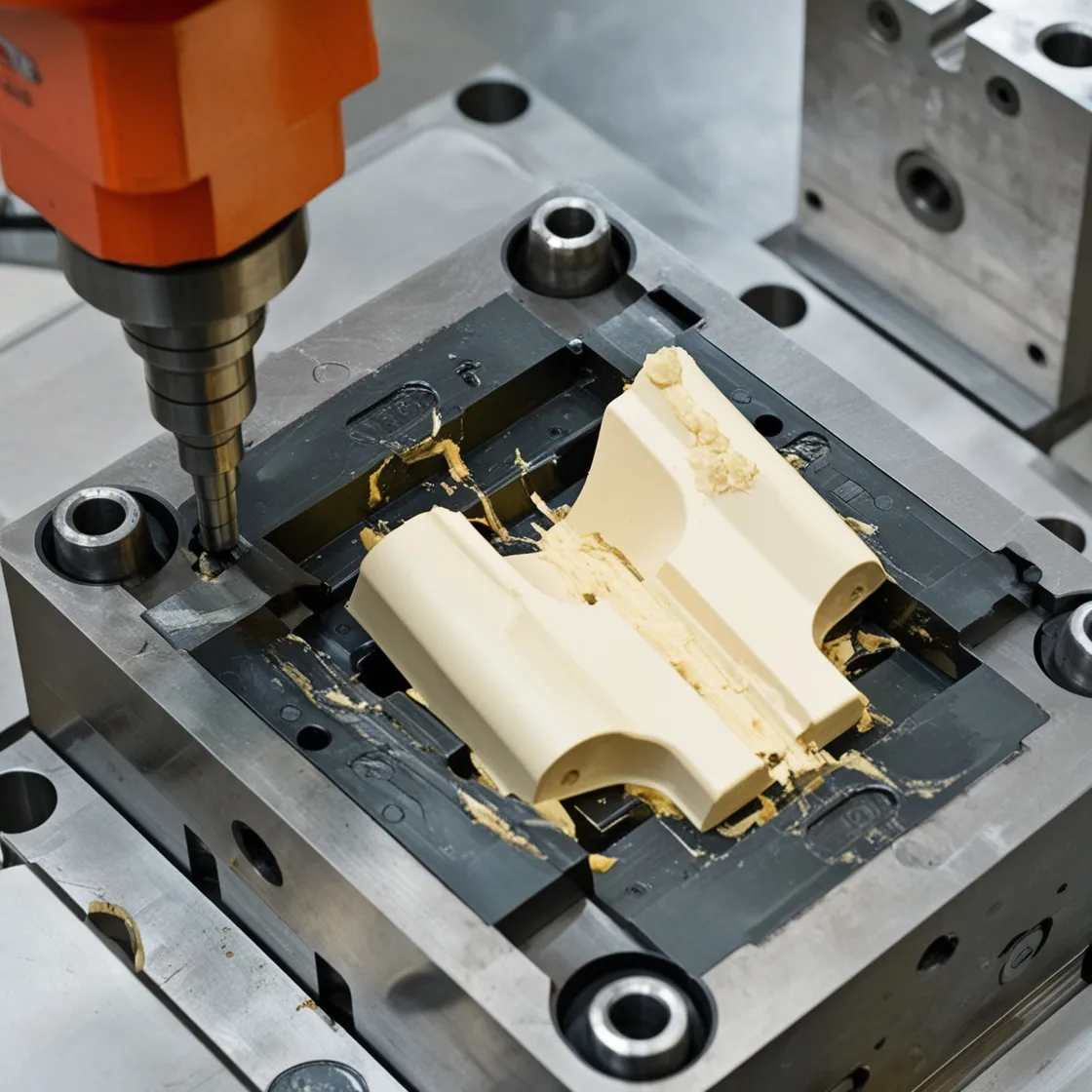

Company News

Company NewsOur team showcased the latest multi-station thermoforming equipment to merchants worldwide. See how international partners are reacting.

Industry Trends

Industry TrendsAs global demand for eco-friendly packaging rises, learn how Mesoforming machines ensure precision forming for compostable materials.